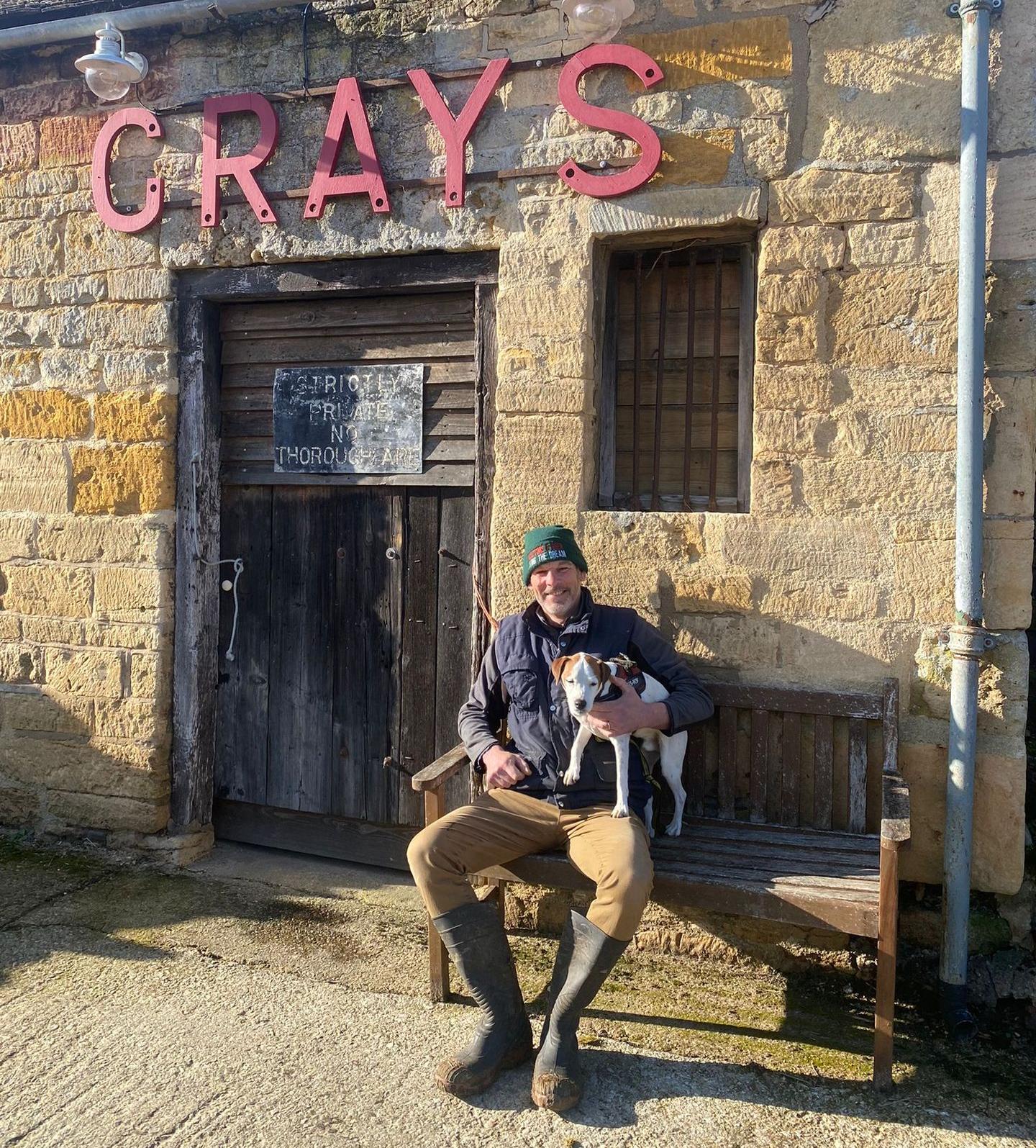

Carl Gray

G Gray Farms Ltd

Setting the Scene

Carl has been farming organically for nearly 25 years since conversion in 1999, after advice from an organic who encouraged to believe in organic as a system. He was already running quite an integrated farm with crops and beef cattle so the transition was not a great leap, and as Carl admits, there was also a conversion in his mentally towards the organic approach.

| Farm Name | Grange Farm |

Cash Crops Area (Ha)

|

68 |

| Farm Size (Ha) | 285 | Herd Size | 150 |

|

Owner/Tenant

|

Mainly tenanted

|

Soil Type(s)

|

Light Sandy,Heavy Clay

|

|

Years Farming (Org)

|

30 (25)

|

Annual Rainfall (mm)

|

700

|

|

Main enterprise

|

Beef suckler herd

|

Total HP

|

1050 |

Rotation Carl has a tried and tested rotation lasting nine years that includes five years of fertility building, used for the cattle, and typical cereals wheat, oats and barley grown, selling wheat and oats for milling whilst keeping the barley to feed on farm or sold if not required.

| 3 years grass, white clover> | winter wheat (soft wheat)> | winter oats> | 2 years grass, red clover> | winter wheat (soft wheat)> | over-winter stubble turnip> | spring barley, under-sown> |

Agronomic Approach

Tillage management involves ploughing out of grass or surface cultivations using heavy times and discs, depending on conditions. The perennial weed burden and soil moisture tends to determine whether to plough, or to surface cultivate.

Weed management includes the use of stale seed beds, comb harrowing in Autumn, sheep grazing in Jan/Feb followed by comb harrowing, and use of a homemade hoe in the Spring. If required a weed surfer will be used for wild oats or a comb-cut borrowed for charlock. There is also a pair of rotary blades on the back of the combine that "mills" weed seed to stop seed return.

| Worst Weeds | Issues |

| Runch | difficulty combining, wet green pods in grain |

| Charlock | competition, combining |

| Wild Oats | block combine sieves and admix |

| Docks | persistent, steel and diesel usage, lower digestibility of silage |

Crop nutrition is managed through the use of leys, manure and digestate. Digestate is applied to grass leys pre-silage making at 20 cubic meters per ha sourced from a crop digester near Evesham. The heavy machinery can be an issue so conditions must be right. FYM from the cattle is turned to compost and applied at 15-25t/ha before spring barley but this can opportunistic and can sometimes be used to top dress arable crops. An Origin fertiliser containing P, S and Ca is also applied on a case by case basis

| Most "reliable" crop | winter wheat, 5t/ha | Least "reliable" crop | stubble turnips for seed |

Key Agronomic Challenges

Biggest Agronomy Question: How to destroy a ley including perennial weeds without using so much steel and diesel.

Climate Challenge:

The increase in extreme conditions and the unpredictability

Machinery

Carl has two drills, a Weaving tine drill used for the wheat and oats and a Kuhn combi drill that creates a finer seed bed for grass and spring barley.

Best machinery purchase: Kuhn combi-drill, used when conditions are too wet for multiple passes or if conditions are too dry. The drill has got Carl out of many tricky situations.

Worst machinery purchase:

John Deere telehandler that would oscillate and bounce on the spot until the windows blew open! There were also reliability issues.

Total horsepower on the farm is 1050hp, with a combine and four tractors averaging 150hp each.

Worst moment in farming

Foot and Mouth in 2001 felt catastrophic, and like the end of the farm.

The biggest organic lesson learned?

The damage that can be done to fields by travelling in poor conditions, which has a greater impact under Organic management.

Where do you see yourself and the farm in 10 years time?

In the Alps! Still farming, with the farm under more environmental schemes on the less productive ground .

What do you know now that you wish you'd known when you started farming organically?

The best ways to manage soil and ways to get the best crop establishment

Best moment in farming

Finishing a successful hay making on the river meadows. It's a lovely traditional practice.

The best organic advice you've received?

From Richard Steele (for those of you who know Adrian, his father) before converting that Organic farming was a truly viable system and business, giving the confidence to convert and embrace Organic farming.

Best piece of advice you'd offer an organic farmer?

Don't plant a cash crop into a poor seed bed.

Did you have an epiphany moment? If so, what was it?

No grand epiphany, it's been slow incremental learning

If you come home at the end of the day and complain to your family how hard a life in farming is, don't be surprised if your kids don't want to go into farming!.

The two bottom pictures (centre, right) show some of Carl's engineering innovations. The Double hitch configuration means the Weaving drill can be attached in one position to drill and then reattached offset by a 12cm to then use the drill to hoe between the rows. The other photo shows a modification on the back of the combine that grinds the straw to destroy as many weed seeds as possible and reduce the volume of viable seed returning to the field. The picture on the bottom left shows a wheat/bean bi-crop - Carl has an interest in this and feels more research is needed on this practice.